Contents

What is the meaning of As-built in construction?

Why are As-built surveys important in construction?

What's the difference between As-planned and As-built?

Are As-built drawings accurate?

How does As-built software work?

Using As-built survey software to close the gap between the site and the plans.

TL;DR: Why As-built software is a must have for construction management.

What is the meaning of As-built in construction?

In the context of construction, the term "As-built" refers to the true representation of a building or structure, either while it's being built or after it has been constructed. The purpose is to create documentation that shows the actual physical conditions and dimensions of all relevant elements in a worksite as they exist in reality, rather than the theoretical design or planned specifications.

For refurbishing an existing property, As-built documentation helps create project plans that take the existing reality into account. In a new-build construction, it helps project managers track what’s being built at the site, monitor work progress and quality, update BIM models with any onsite changes, and resolve engineering challenges faster. Read here how to digitise and leverage BIM models in refurbishment projects.

As-built surveys help document the onsite conditions as they truly are in reality. This allows to rectify discrepancies in previous documentation, or to detect deviations from work specifications.

As-built surveys help document the onsite conditions as they truly are in reality. This allows to rectify discrepancies in previous documentation, or to detect deviations from work specifications.

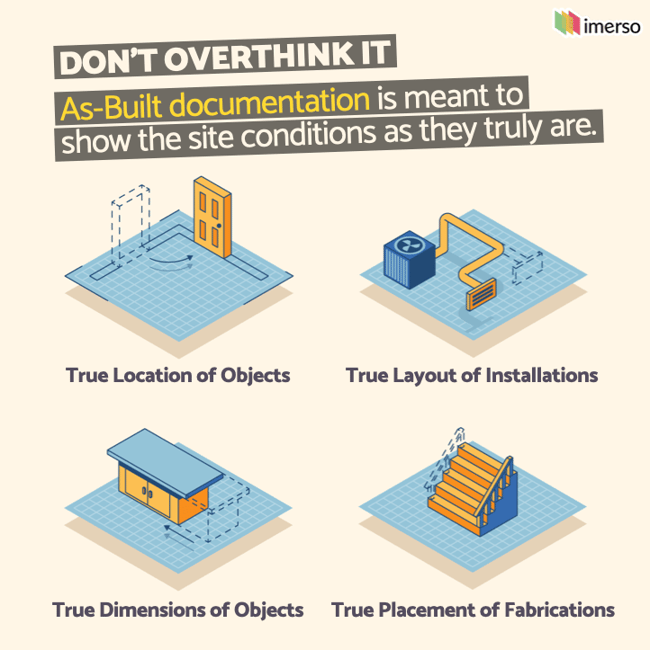

To have complete and useful As-built documentation, it's important to consider the following:

- Object Locations: Is everything installed in its correct place? Note down all changes to the location of elements like doors, wall openings, window casings, plumbing, millwork, and any other essential features.

- Object Dimensions: Do the onsite objects occupy the same volume, or floor footprint, as they should? Even if something is installed in its correct place, this can still be trouble if the installed object has a different dimension than documented. Write down all modifications to the dimensions of the elements installed at the site.

- Layout of Installations: This is a mix of the two considerations above. Some installations, like an HVAC or MEP system, are comprised of multiple individual components. Consider the overall installation of the system as a whole and how it deviates from the existing documentation. Note down the components that deviate.

- Placement of Fabrications: Similar to seeing an onsite object installed in a different location, you should also note down specific fabrications such as power outlets, lighting fixtures, staircase railings, or partition walls.

- Materials Used: Do the materials used in all onsite installations match those registered in the available documentation? Note down any relevant deviations.

What is an As-built survey?

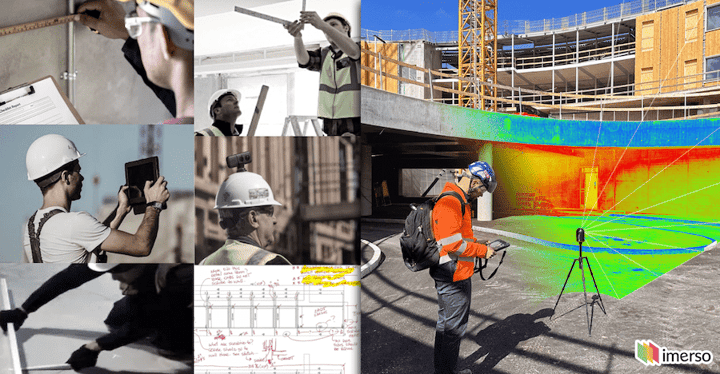

An As-built survey involves measuring and documenting the precise conditions of a construction site or property. As-built surveys can be as straightforward as documenting the site conditions using photographs and manual measurements. You can rely on available floor plans and schematics and make notes on any deviations you find at the site. This traditional approach often involves using a red marker on a paper print-out of the schematics, earning their common name of Red-Line Drawings. These drawings can then be accepted as "As-built" documentation or used as a reference to update other documents.

As you can imagine, relying solely on the traditional Red-Lining approach can be a time-consuming and inefficient process, especially when dealing with larger construction sites where data precision and speed are vital. For these, it is far more advantageous to utilise specialised surveying equipment such as 3D Laser Scanners for conducting As-built surveys. These cutting-edge devices have the ability to capture millions of measurements within minutes, boasting millimetre-precision. As a result, they effortlessly create a digital replica of the jobsite that is remarkably true-to-life. Read more here about the use of 3D Laser Scanning in construction.

As-built documentation is not as efficient or accurate when done manually compared to an As-Built survey with a 3D laser scanner, which captures both images and millions of measurements in seconds, with millimetre precision.

As-built documentation is not as efficient or accurate when done manually compared to an As-Built survey with a 3D laser scanner, which captures both images and millions of measurements in seconds, with millimetre precision.

Why are As-built surveys important in construction?

As-built surveys demonstrate the facts about the actual onsite conditions.

This allows not only accounting for what has been built but also if all installations meet the planned specifications. As-built documentation serves multiple purposes in construction, including record keeping, quality control, verification and compliance, and facility management. It provides a valuable historical record, ensures work aligns with plans, demonstrates compliance, and aids in facility maintenance.

Managing a construction project without an efficient method of

|

If the documentation shows one thing, but the onsite reality is different, project teams will suffer from hidden surprises and be forced to improvise on the spot – leading to even more changes from the available documentation. This is leading modern project managers to look for better solutions than traditional manual approaches, to routinely capture accurate and detailed information about the onsite status. In some cases, the lack of this information can lead to disaster.

Without the ability to closely track the true onsite status using As-built software, construction managers are blind to upcoming collisions and costly surprises that plague every project.

Without the ability to closely track the true onsite status using As-built software, construction managers are blind to upcoming collisions and costly surprises that plague every project.

What is the difference between As-planned and As-built?

As the name suggests, As-planned refers to the documentation of what has been planned in a construction project. Conversely, As-built refers to what has actually been built in reality. The difference between the two gives rise to the so-called “As-planned vs As-built” methodology of tracking progress in construction projects. Comparing what was planned to what has been built allows us to identify “float” between work packages (such as a certain planned activity being completed earlier than expected, allowing subsequent teams to start earlier), or detect delays that might endanger upcoming work sequences.

Moreover, mismatches between the plans and the onsite reality can highlight errors or out-of-tolerance installations that, if caught early, can prevent costly rework delays and disputes that negatively impact the entire project. Therefore, having an effective and reliable method for routinely capturing As-Built information during the construction phase presents an enormous value for project management and quality assurance.

Are As-built drawings accurate?

Well, they should be, right? As-built drawings supposedly reflect the exact onsite conditions. If they are inaccurate, they don’t deserve the label “As-Built” and shouldn’t be trusted as such.

The better question is: How do you know whether As-built documents are accurate?

The accuracy and detail of the documentation depend on the as-built survey method. While some situations may only require basic measurements and photos, a more detailed survey can identify varying angles in wall layouts, uneven floors, and non-compliant ceiling heights. Project managers must ensure that their As-built information is accurate, current, and sufficiently detailed based on the complexity and risk profile of their projects.

This is fundamental for effective construction supervision, as project managers must rely on the As-built documentation available to monitor how the project is going.

To ensure that the reported documentation is correct, it must be verifiable.

For this, we turn to As-built survey software.

How does As-built software work?

As-built software helps project manager capture and analyse As-built information in their construction projects. These tools are invaluable in detecting onsite work deviations from the plans, as well as updating the building plans and other documentation with any onsite changes.

Most common data environment solutions (CDEs) provide a rudimentary form of As-built software since they are integrated with mobile apps for punching checklists during onsite visits and capturing photos or even 360 cameras of the site. Taking a photo, or even a 360 image, can show you what objects have been installed, but not if those installations meet the specified installation requirements. For this, modern 3D laser scanners are a much more effective solution for capturing and analysing the As-built conditions. Read here about the different uses of 360 cameras and 3D laser scanners in construction projects.

For an effective oversight of project status, As-built software must not only provide visual data that users can look at, but also capture and analyse vital volumetric data like measurements, volumes, surface levels, and installation tolerances.

Effective As-built software gives you two superpowers:

- A method for capturing onsite conditions easily and accurately, and

- A method for automatically analysing the resulting data.

As-built software helps capture the real onsite conditions fast and accurately

Using 3D laser scanners in construction is often seen as difficult or scary, and likely requiring trained experts. Luckily, modern As-built software like Imerso makes 3D laser scanning so easy that this can be used by anyone as a daily routine. This not only captures high-definition 360 images but also millions of high-accuracy measurements in real 3D – effectively creating a digital version of the jobsite as it truly is.

With the press of a button, As-built software like Imerso allows capturing the true onsite reality in seconds, by making 3D laser scanning easy to use.

With the press of a button, As-built software like Imerso allows capturing the true onsite reality in seconds, by making 3D laser scanning easy to use.

As-built software automatically checks the captured information about the site

Users can then access the jobsite reality remotely from any browser as a Digital Twin, and take any measurements, volumes and surface flatness measurements, among other functions.

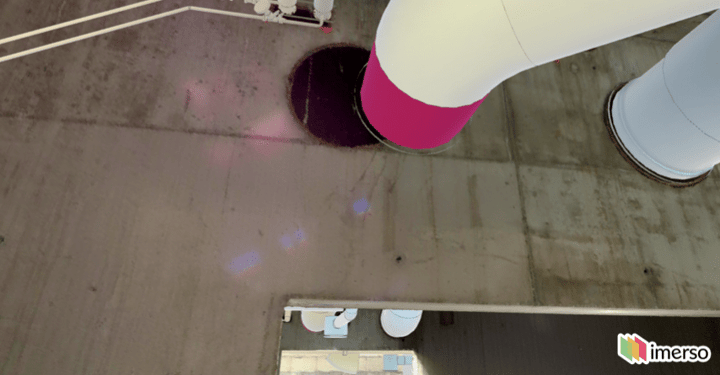

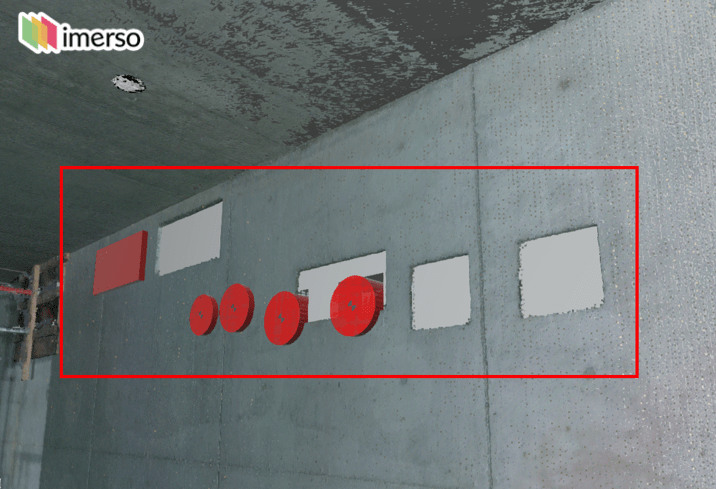

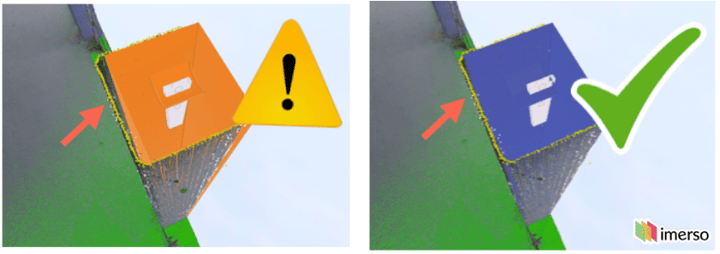

Most crucially, Imerso is the only As-built survey software that automatically analyses the jobsite for compliance with the building specifications. This allows instantly reporting about the onsite status and catching any problematic onsite deviations, including a variety of issues impossible to see visually in photos or 360 images — Providing project managers with unprecedented site supervision abilities.

Imerso automatically checks the As-built conditions, reporting on work status and flagging problematic deviations early, without human subjectivity.

Using As-built survey software to close the gap between the site and the plans

By enabling project managers to capture their jobsite routinely with such a level of accuracy and detail, several opportunities emerge to automate previously laborsome tasks, as well as to eliminate costly project risks. Imerso can use the As-built data to predict upcoming clashes, enabling users to stop problems before they happen.

As-built software allows to quickly detect mismatches between the onsite conditions and the planned design, including any issues invisible in photos to the naked eye.

As-built software allows to quickly detect mismatches between the onsite conditions and the planned design, including any issues invisible in photos to the naked eye.

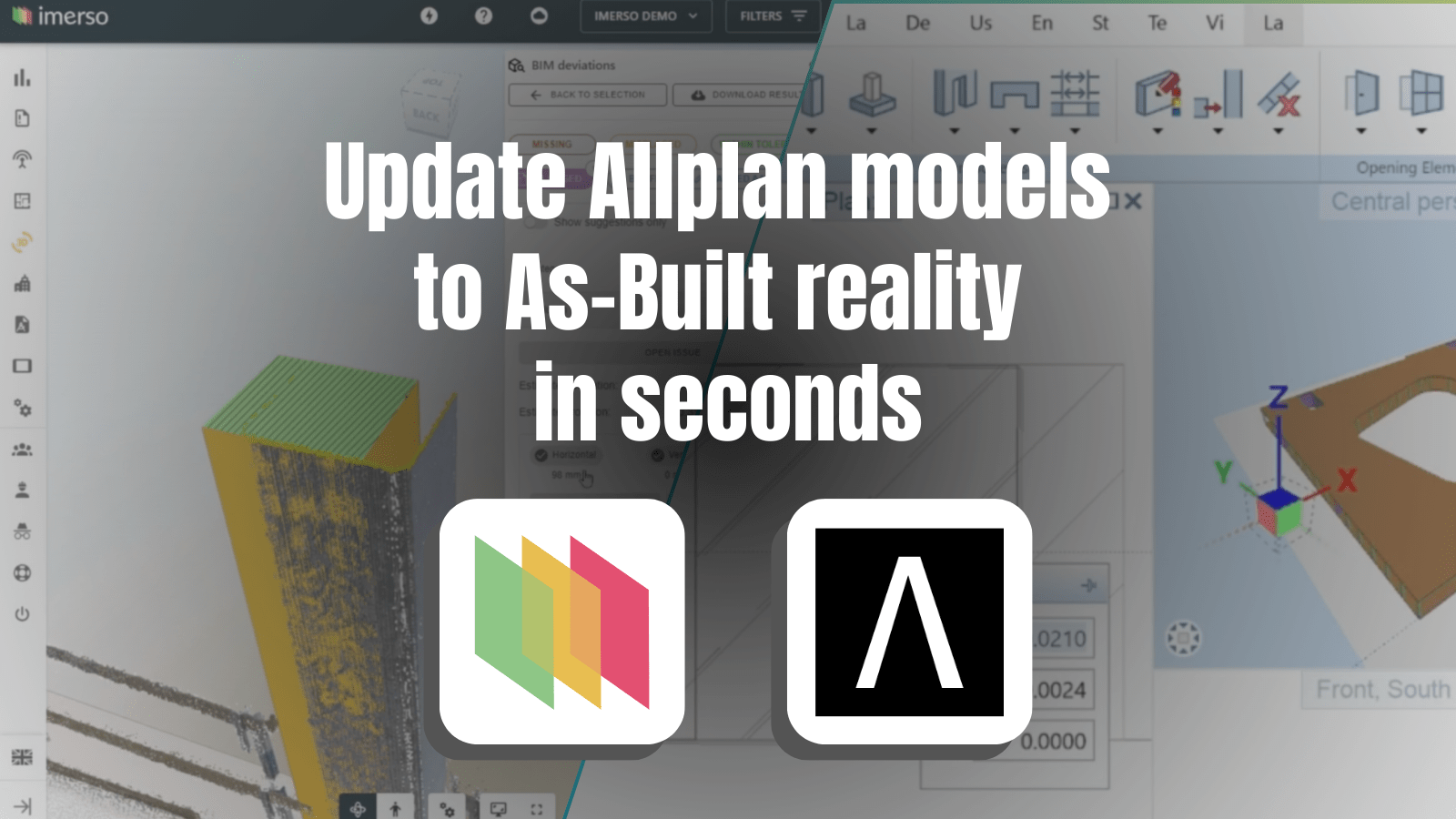

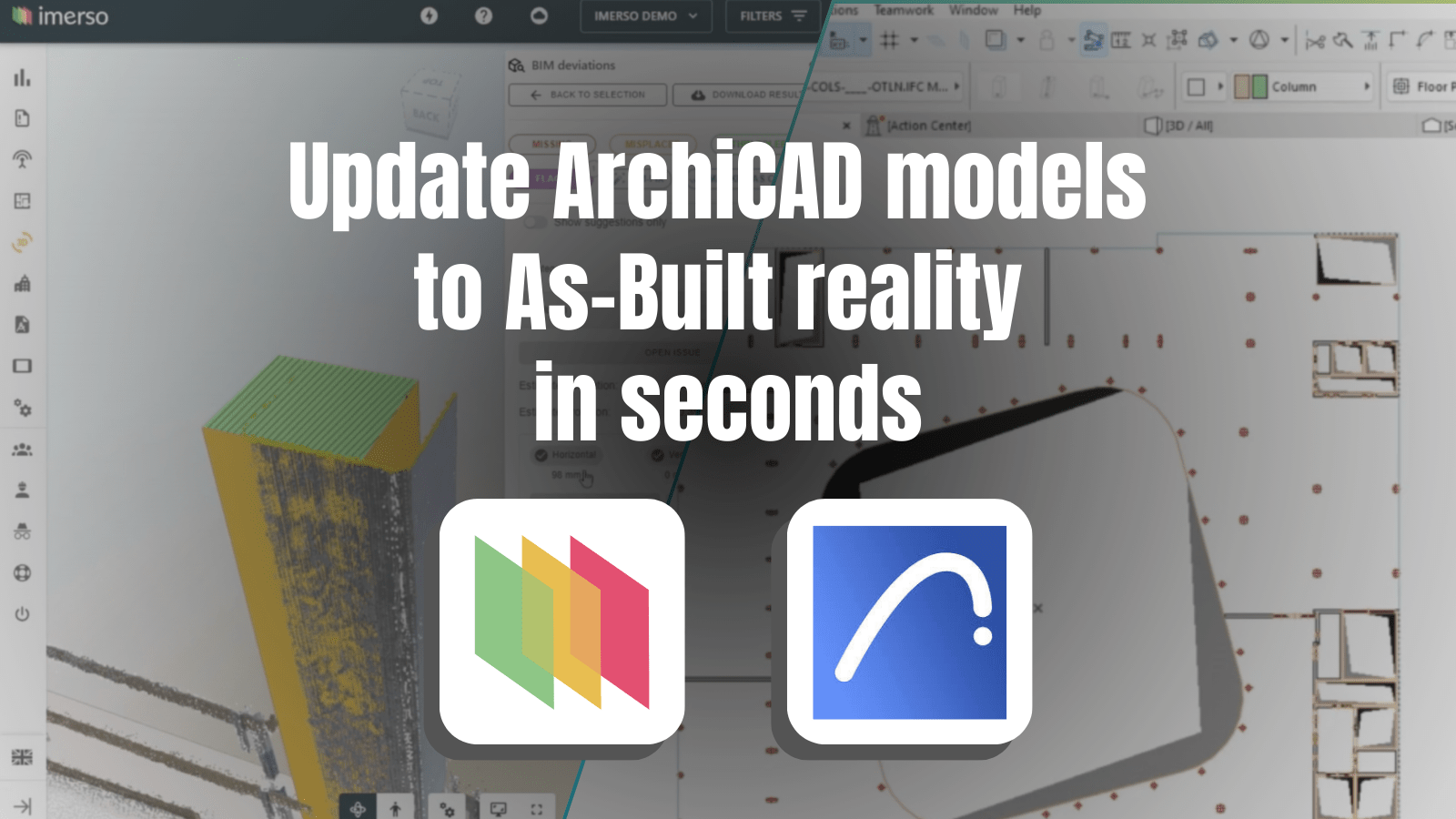

The platform also enables automatic updating of the BIM models to the real onsite reality at the press of a button – eliminating countless hours of manual modelling work. This helps keep the BIM models relevant throughout the construction phase, as well as ensuring accurate deliverables at Handover.

Having such detailed information readily available in the online platform (that all team members can access remotely from any browser), allows designers and engineers to rapidly get context and any measurements they need for promptly resolving engineering issues. Imerso customers are reporting increases above 96% in the speed of addressing onsite issues since starting to use the platform.

Imerso leverages As-built survey data to keep BIM updated to the true onsite conditions automatically, eliminating countless hours of manual modelling work.

Imerso leverages As-built survey data to keep BIM updated to the true onsite conditions automatically, eliminating countless hours of manual modelling work.

Clients are using their online "Digital Twins" to leverage current As-built survey data, allowing for remote virtual visits and enhanced access to information. This not only enhances communication and collaboration among project partners in a construction setting but also facilitates reporting and managing relationships with end clients. As a result, the use of reliable As-built information greatly improves transparency and accountability levels.

TL;DR: As-built software is a must-have in any construction project

As-built documentation plays a crucial role in every construction project, ensuring that the available information is accurate and detailed. Implementing effective routines to capture reliable and detailed information about the true status of the job site has become an essential strategy for any project.

With the increasing scale and complexity of construction projects, As-built survey software has become an invaluable tool for gaining insights into what is happening on the jobsite. It provides accurate information that is free from human subjectivity and eliminates the need for time-consuming visits.

About Imerso

Imerso is a software platform that combines BIM, Reality Capture, and AI technologies to automate construction site supervision and quality inspections with one simple workflow. We help construction companies cut project risks and delay costs with real-time monitoring of site status and work quality.

For additional reading, check out the 7 Powerful ways of using Imerso to supercharge your construction projects.

.png?width=350&height=147&name=Imerso_Logo_A4_White_Transp%201%20(1).png)