List of Superpowers

- Get routine site documentation with much better quality at a fraction of the effort

- Protect your budget by eliminating costly surprises and delays proactively

- Automate time-wasting routine tasks to focus on value creation

- Predict and resolve upcoming issues before problems occur

- Double your speed to address change requests and solve site issues

- Expand your own team's internal QC/QA abilities without costly external services

- Eliminate idle time waiting for information and in-person site visits

- Remove guesswork from team discussions and keep everyone on the same page

- Cut planning time in refurbishment projects to 30% while reducing risk

- Keep BIM Models updated to the site reality in real-time as you build

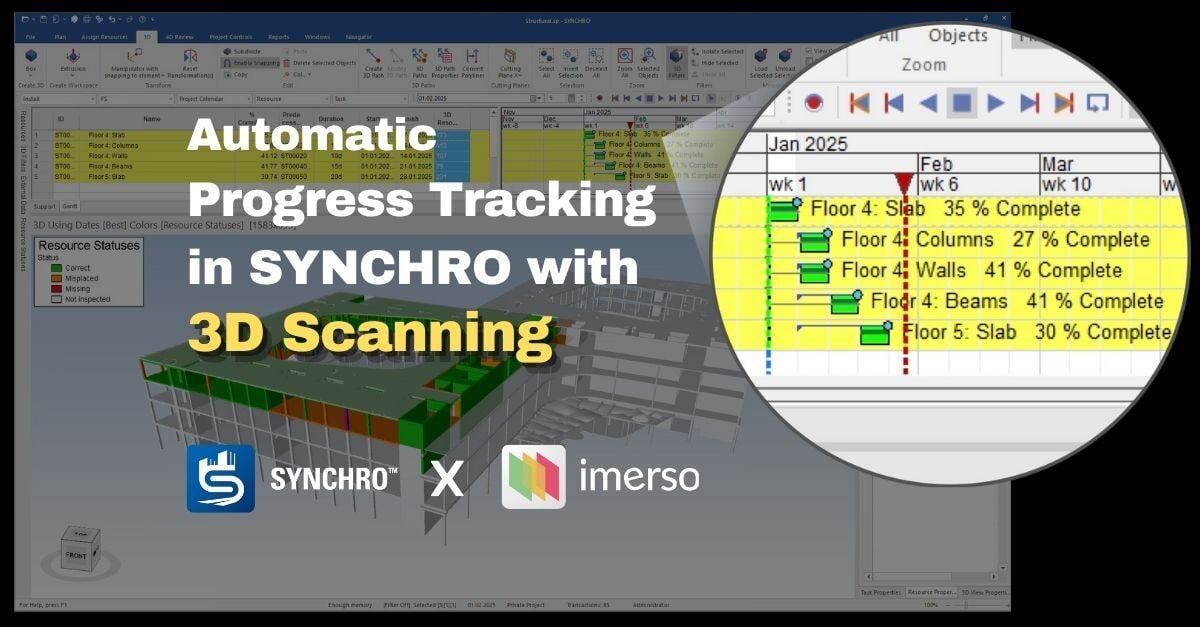

Construction managers are always looking for effective ways to track their projects. The new-generation solution like Imerso leverages BIM, Reality Capture, and AI technologies to automate site supervision workflows, and routinely track the onsite work quality and progress against the plans.

Here are the top 10 superpowers all construction managers can unlock this year with Imerso.

➔ ➔ Take the Free Tour of Imerso here ➔ ➔

Get better site documentation at a fraction of the cost and effort.

Documenting completed works and the overall status of the jobsite is a continuous and laboursome effort. There is typically a tradeoff between time spent (ie. cost), area coverage, and data accuracy, which leads to the typical QA/QC approach of random sampling.

Using photos or even 360 Cameras to track the site status can be a good solution to get visual documentation, at the expense of measurements, details, and data accuracy. Analysing the work status requires more than just photos: read on the pros and cons of 360 Cameras vs Laser Scanners in Construction to learn more.

Imerso breaks that tradeoff by enabling site teams to use 3D Laser Scanners entirely by themselves, without the need for expensive third-party services, and at much faster speed and convenience than traditional construction scanning workflows. In a matter of hours per week, a single user can capture every corner of the site.

This produces millimetre-accurate documentation in true-to-life 3D and dozens of 360 panorama images, letting teams track every stage of construction fast and efficiently.

We can keep models accurate to what is built and hand over documentation continuously, instead of at the very end.That saves us a lot of time.Magnus Bjørndal JacobsenHead of Innovation, Betonmast. |

Once captured, all of this data is instantly available in the online platform for access by any remote teams. Simultaneously, the data is analysed against the project specifications in the BIM execution plans, to alert of any problematic issues and update the BIM models to the latest onsite changes.

Whaaaaattt...? 🤯🤯🤯

We'll get to that in a second!

Protect your budget by eliminating costly surprises and delays.

The sequential nature of construction projects leaves every team dependent on the results of the previous ones who worked in the area before. Installations that deviate from the planned specs and tolerances, or lapses in construction quality, typically stay hidden only to surface at a later time and cause havoc in the form of costly rework and delays.

By capturing and analysing the completed onsite work against the project plans on a routine basis, Imerso flags a variety of suspicious cases for project leaders to review every week.

Imerso enables any of us to scan an area in the morning and have a full analysis ready to review after lunch.This really improved how we approach work quality and interface issues.Doing this on a daily basis like this was not possible before.Anders KaasProject Manager, Region Hovestaden |

By leveraging unique As-built information in the form of 3D Scan data, Imerso detects a variety of issues impossible to find with other approaches, whether using manual checklists, photos, or 360 Cameras. This provides an unprecedented opportunity to resolve issues months in advance of any onsite complication while the responsible teams are still at the site.

This unique risk mitigation approach leverages automation to produce significant savings by eliminating avoidable expenses. In addition, it promotes a smooth handover from one team to the next, at every step through increased accountability and visibility for all teams.

Automate time-wasting routine tasks to focus on value creation.

Construction is notorious for its heavy reliance on outdated manual workflows, which are a massive hindrance to productivity and lead to slower progress. Therefore, automating such tasks with modern approaches leads to significant positive effects that scale beyond the specific task.

By making 3D laser scanning in construction so easy that even interns can do it, Imerso users are documenting the onsite As-built conditions 53x faster than their competitors still relying on photos and manual checklists, while using only 2% of the resources.

Simultaneously, by automatically analysing every object captured in the scan data against the specification of the project plans, Imerso can instantly report on the work quality of completed works as well as the progress so far. Imerso users are seeing a 14x increase in labor efficiency onsite supervision tasks, while using less than 7% of the resources of other approaches.

As a result, a single Imerso user can outperform an entire team, such as in the case of NHN, whose project manager delivered in two months the work it had budgeted for a team to take an entire year.

The construction world is still pretty conservative.

|

The truth is that nobody likes seeing their time wasted on ineffective and pointless tasks. Our customers want to see their efforts drive real value and measurable results and see that this in turn creates a rewarding work environment for all teams involved.

Predict upcoming issues and resolve them before problems occur.

In addition to reporting on the current work status and the quality of completed works (are there any objects onsite that deviate out-of-tolerance from the project specifications?), Imerso's AI technology also analyses whether the plans for upcoming installations still fit as predicted.

In other words, Imerso continuously checks that the building plans are still buildable, and produces alerts otherwise. This allows construction managers at leading contractors like AF Gruppen to stay ahead of costly surprises and solve problems before they happen, with an average cost-saving impact of over €15,000 per issue flagged by Imerso.

Imerso gives us confidence that everything we’re building is accurate in accordance to the drawings, and within the specified tolerance requirements.We now have much better documentation of everything that has been done, not just random samples or photos.Håkon GrandeBIM Manager, Lag Entreprenør |

This proactive monitoring of the construction status allows not only saving avoidable costs, but even preventing disastrous compliance violations that could prevent the property from entering operations entirely. Check out how Imerso is being used to verify compliance of Fire Safety installations automatically in a € 1 Billion hospital construction project.

Resolve change requests and site issues at twice the speed.

Imerso customers are seeing a significant acceleration in the time to respond to requests and resolve site issues. This is thanks to the high quality of As-Built data available in the digital twin platform, which allows any remote partner teams to have easy access to the jobsite virtually. This includes access to a wide breadth of information and context about onsite problems, that allows faster communication and the outlining of engineering solutions at a quicker pace.

Combine this with easy data sharing features, OpenBIM and international formats, file interoperability and API integrations with popular tools like CDEs, Solibri, Autodesk, etc, and you'll find your teams exchanging information and collaborating at twice the speed.

In the past, only CAD engineers could really understand and analyse point clouds to detect future problems.With Imerso, we now have a fast and easy solution available to check the onsite reality directly against BIM.Onsite teams don’t need any knowledge of complex engineering CAD tools to run Imerso.Johannes Ris, Project Manager / CTOByggstyrning |

Teams like Byggstyrning, a leading project management and engineering firm that leverages pre-fabrication as a strategy to accelerate their projects, turned to Imerso to streamline their workflows and eliminate hassles and delays from their sites. The team uses the data in the platform to plan and order materials on time as needed and resolve any issues in collaboration with their manufacturing partners well in advance of the elements being sent to the site.

Expand your own team's QC/QA abilities without costly external services.

This is another blind spot typically left open by other site supervision approaches: few teams are applying methods to verify completed works that meet strict industry standards like the DIN-18202 protocol. This is understandable, as these methods can be complicated and difficult to deploy, and as such are left to expert third parties.

With Imerso, you can apply automated rules to verify work compliance with the DIN-18202 standard in seconds! This includes verifying flatness in roofings and floor slabs, surface levels of structural walls, verticality of columns, etc, at the press of a button.

Your teams can conduct this test completely in-house, without the need for expensive specialists, like leading construction engineering firm Drees & Sommer who have now deployed Imerso's inspection routines across their jobsites. You can read how they do it here!

Avoiding rework costs and delays is great.But the biggest hidden risk is that the building is not allowed to open operations because of any overlooked compliance issues.Imerso’s impact on reducing this risk is invaluable.Anders KaasProject Manager, Region Hovestaden |

Eliminate idle time waiting for information and in-person site visits.

Leverage the Imerso online digital twin to give all partners remote access to the virtual jobsite. This lets you cut idle time waiting for information, accelerate discussions and collaboration, and make unnecessary site visits a thing of the past and an unacceptable excuse to postpone a decision. Read more about how to Close the Information Gap with As-built Data.

Imerso customers like Statsbygg saw a 50% decrease in the need to travel to the jobsite to get missing information, like context, work status, or measurements, while increasing the number of decisions in weekly ICE meetings. Property owners like KLP Eiendom are even leveraging Imerso to deliver guided virtual visits to their jobsites to prospect customers, giving them an update on the state of construction and increasing customer involvement in their projects.

Eliminate guesswork and keep all your teams on the same page.

Closing the gap includes removing blind spots at the site. Imerso helps you do this by vastly increasing your inspection coverage. In other words, with less effort you can now verify all work areas, including those you would not usually have resources to fully check via traditional approaches. Read here how An Imerso user checked work status at a 12.000 m2 site in a single day.

Within two months of deploying Imerso at their sites, general contractor Per Aarsleff and their daughter company e.Klink saw impressive results:

- From 15%, the teams are now checking 100% of all completed at their sites.

- This significant boost came at no increase in time spent, in fact they saw a reduction in the onsite verification time.

- The captured data helped their teams increase work productivity, while project risk went down.

Reduce planning time to 30% in refurbishment projects and cut risk

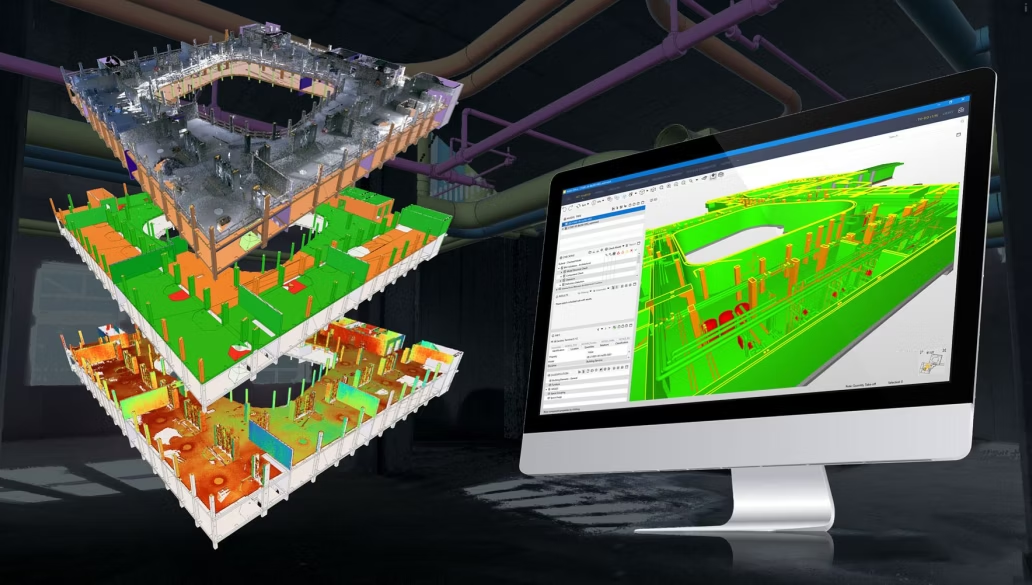

One of the major challenges in refurbishing existing buildings is the lack of reliable documentation about their current conditions. Available documentation is typically outdated, as well as too low detailed to be used for planning purposes. For example, very often there are only basic 2D-floor plans available, featuring questionable measurements, lacking notes of any past modifications, and not providing height dimensions or details of existing installations.

It would be ideal to capture the property’s conditions with 3D Laser Scanning prior to commencing the design, as this would allow to incorporate key building elements into the design basis from the get-go. But this is rarely done, since the building is often still occupied by a tenant, and the building must also be tripped down to expose the building fabric, which is otherwise hidden by drop ceiling tiles and other such installations.

As a result, fit-out contractors are forced to initiate design tasks prior to surveying the property, leaving uncertainty in the drawings and how those will affect the construction stage.

Imerso gives your teams two enormous advantages in Refurbishment projects:

- Easy and fast 3D Laser Scanning, to rapidly capture the As-built data as soon as possible, and

- Automatic verification of the early design models against the real property, to detect and resolve mismatches well in advance of material purchasing and the start of construction.

This has helped giant property developers like KLP Eiendom to capture their existing properties rapidly and effectively with 3D scans, and bring the resulting data early into the design and planning process of their refurbishments.

Imerso makes the job considerably easier for us and our various advisers, who actually don't need to be physically present at our sites.It provides much better quality assurance for the project, and we know that it will be built according to the drawings.Erik SkjønhaugProject Manager, KLP Eiendom |

The teams were able to resolve mismatches between reality and the models which would add significant unnecessary risks, costs, and delays to the project. In addition, leveraging the accuracy and reliability of the As-built data, the designers were able to find better, more sustainable design choices, implement more effective waste management, and explore circular economy principles, all of which are earning their projects higher BREEAM Sustainability Scores.

Keep BIM Models updated to the site reality as you build.

The Handover stage can be a complex and time-consuming process, and is typically a last-minute rush to gather all finalised As-Built documentation. The trouble is that by this time most installations are occluded and no-longer visible, and your teams do not have the time nor man-power to verify the entire jobsite, and so this will be a random sampling best-attempt.

The Handover stage can be a complex and time-consuming process, and is typically a last-minute rush to gather all finalised As-Built documentation. The trouble is that by this time most installations are occluded and no-longer visible, and your teams do not have the time nor man-power to verify the entire jobsite, and so this will be a random sampling best-attempt.

↑ Sounds familiar? 😓😓

There's a better approach: Don't leave this to the end!

Imerso makes it easy for your teams to capture the As-build documentation fast, and effectively through laser scanning. Use this data to your advantage.

Very intuitive solution, anyone can use itNow we have better control and smoother processes.This saves us a lot of time, which we can use to negotiate better contracts, follow up on the project, and manage project changes proactively.Christopher CarlsenHead of Innovation, Betonmast |

Your teams can keep BIM models automatically updated to any onsite changes as you build, and verify the actual As-Built reality within millimetre precision. Not only does this eliminate countless hours of manual modelling work through automation, it also saves headaches and stress at the final stages of the project. Read more about the vital role of tracking As-Built data throughout the construction phase.

Conclusion

So there you have it! The 10 Superpowers Imerso can unlock this year on your construction projects. With a starting time of under 3 days, Imerso is a no-brainer! Drop us a line to learn more, we'd be happy to tell you all about Imerso and how it can help your teams.

About Imerso

Imerso is a software platform that combines BIM, Reality Capture, and AI technologies to automate construction site supervision and quality inspections with one simple workflow. We help construction companies cut project risks and delay costs with real-time monitoring of site status and work quality.

.png?width=350&height=147&name=Imerso_Logo_A4_White_Transp%201%20(1).png)