Contents

The Haunting of the Faulty Foundation

The Fright of the Displaced Hollows

Spooky Fire-Stopping Secrets

The Scare of the Creeping Slopes

The Haunting of the Faulty Foundation

%20(1)%20(1).png?width=485&height=420&name=Untitled%20design%20(3)%20(1)%20(1).png)

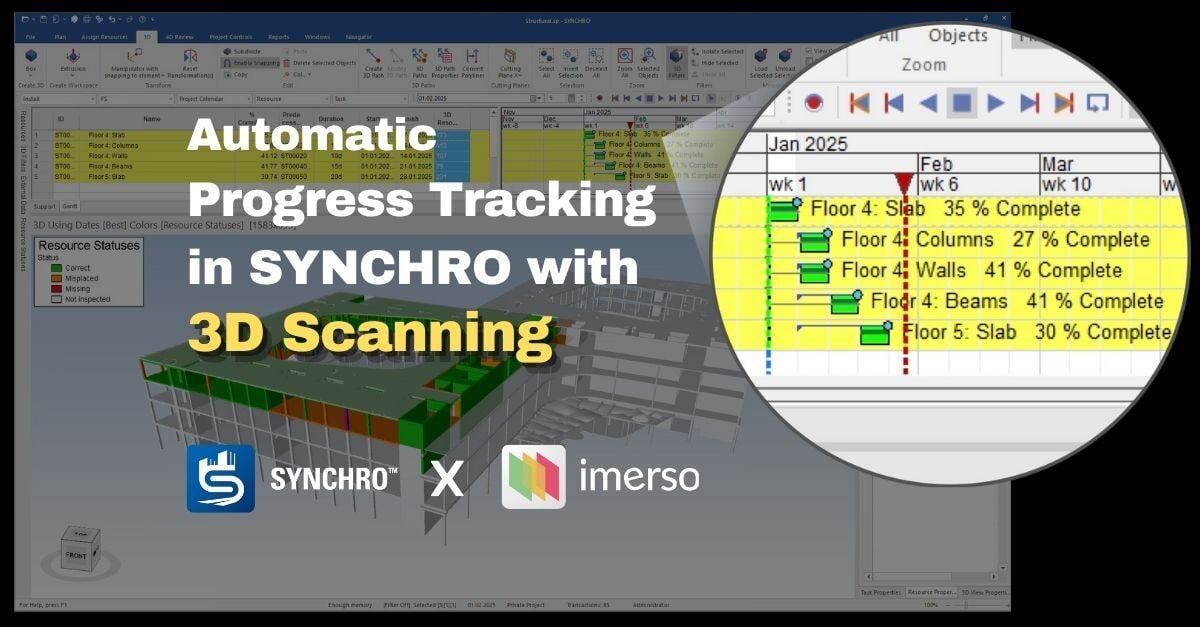

In the eerie moonlight, the construction site for a major 65.000 m2 new university campus stood like a dark fortress. The general contractor had orchestrated the groundwork for months. Their team toiled diligently to lay the foundation for what would soon be one of the largest centers of learning in the country. As the days crept on, the team's exhaustion gave way to anticipation. They had installed the intricate rebar framings and placed the formwork casts in precise locations for pouring the concrete walls in place. But unbeknownst to them, an ominous secret lurked beneath the surface.

A lone Imerso user had an inkling that checking the placement of the forms for the foundation walls was worth the effort. A textbook "better safe than sorry" situation. If misplaced, the prospect of costly tear-downs and extensive reworking would be an enormous setback, or even worse, reengineering the entire plans to accommodate for such unplanned changes. He decided to take a 3D scan of all the formwork and verify all installations in the Imerso platform.

With only two days left until the planned concrete pouring was to begin, the user revealed the results to the team. The data painted a chilling picture. Several casts were misplaced far from their accepted tolerance, and carrying on with the concrete pouring would lead to disaster. With little time to spare, the project managers alerted the responsible teams to not initiate the pouring. The solution was easy: move all misplaced formwork to the correct place and rectify any incorrect rebar installations. With this done, the team was able to correctly build the foundations first-time-right.

Like a survivor emerging from a horror movie unscathed, the message spread to increase the use of Imerso's inspection checks at the junctions between work packages. The ability to quickly verify and approve completed works before subsequent teams take over promoted confidence and a good work rhythm throughout the project. But the memory of that night would continue haunting them forever.

The Fright of the Displaced Hollows

%20(1).png?width=635&height=437&name=Screenshot%202023-10-31%20at%2009.15.59%20(1)%20(1).png)

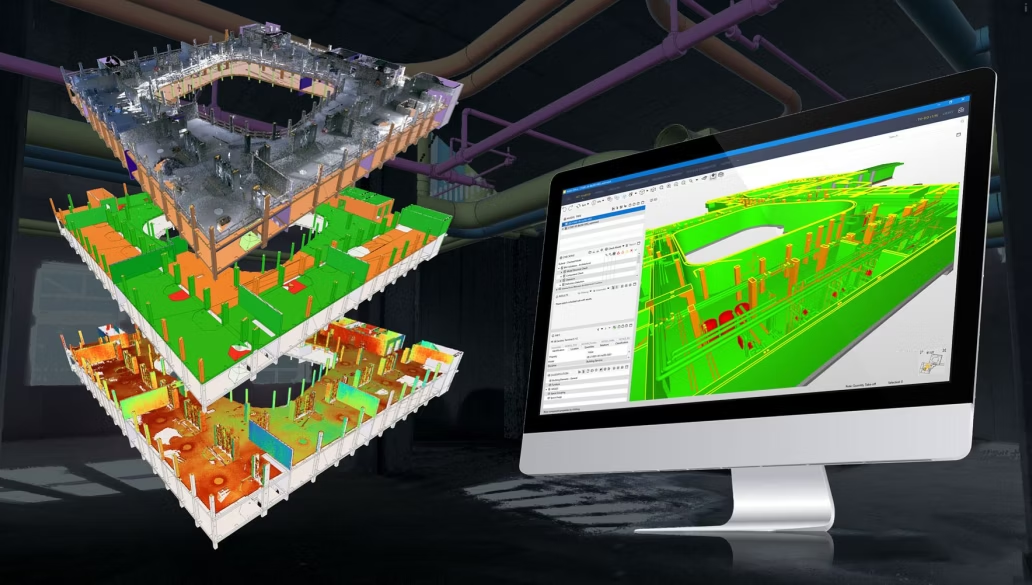

On a misty, early morning, I received a phone call that gave me goosebumps. The call came from one of our largest subcontractors, responsible for installing intricate technical components once the concrete superstructure was complete. As the project's critical phase approached, the subcontracted teams were getting anxious for information about the current status onsite. They were calling me for confirmations, eager to allocate their resources as planned.

I felt the weight of their trust on my shoulders. As a project manager, I sought to assure them that preparations were underway for them to commence their work. But I couldn't shake that uneasy feeling, so I resolved to pay a visit to the site. This wouldn't be a casual inspection; I saw a golden opportunity to take my 3D scanner and capture the current status of works, with the idea of automatically verifying compliance with the building plans. If all is going according to plan, there should be no surprises at this point. The onsite teams, confident of their progress, dismissed the need for such fancy processes. At my insistence, the onsite leaders reluctantly guided me through the most recently finished sections of the structure, demonstrating their progress.

Within a few hours, the scans were uploaded and analyzed. My jaw dropped at the results. Nearly every structural opening in the areas I toured was flagged with an error, deviating from our carefully crafted plans. Some openings had been built with the wrong shape, others were positioned incorrectly, and many were simply missing. The realization hit me: these were just the areas I toured today. What other deviations remained hidden across the site, waiting to emerge?

Armed with this unsettling information, I urgently convened meetings with my team leaders to tackle the impending crisis. The subcontractor teams were on the brink of a disastrous surprise should I green-light their start dates. They would quickly find they are unable to perform their tasks due to these structural errors, in the project phase with the highest number of teams working in parallel. This would bring tremendous delays and extra costs to the project: a firestorm. With the vast amount of data now at our disposal, my teams swiftly devised solutions, calling for onsite rework where possible and negotiating with subcontractors to accommodate the detected changes in revised plans. The ticking bomb had been defused and disaster averted.

Detecting these issues early and proactively resolving them, we spared our project from impending horror. But this was a close call. Too close. From that day onward, I'm swearing by the importance of routine automatic inspections at every step of our project. No more surprises.

Spooky Fire-Stopping Secrets

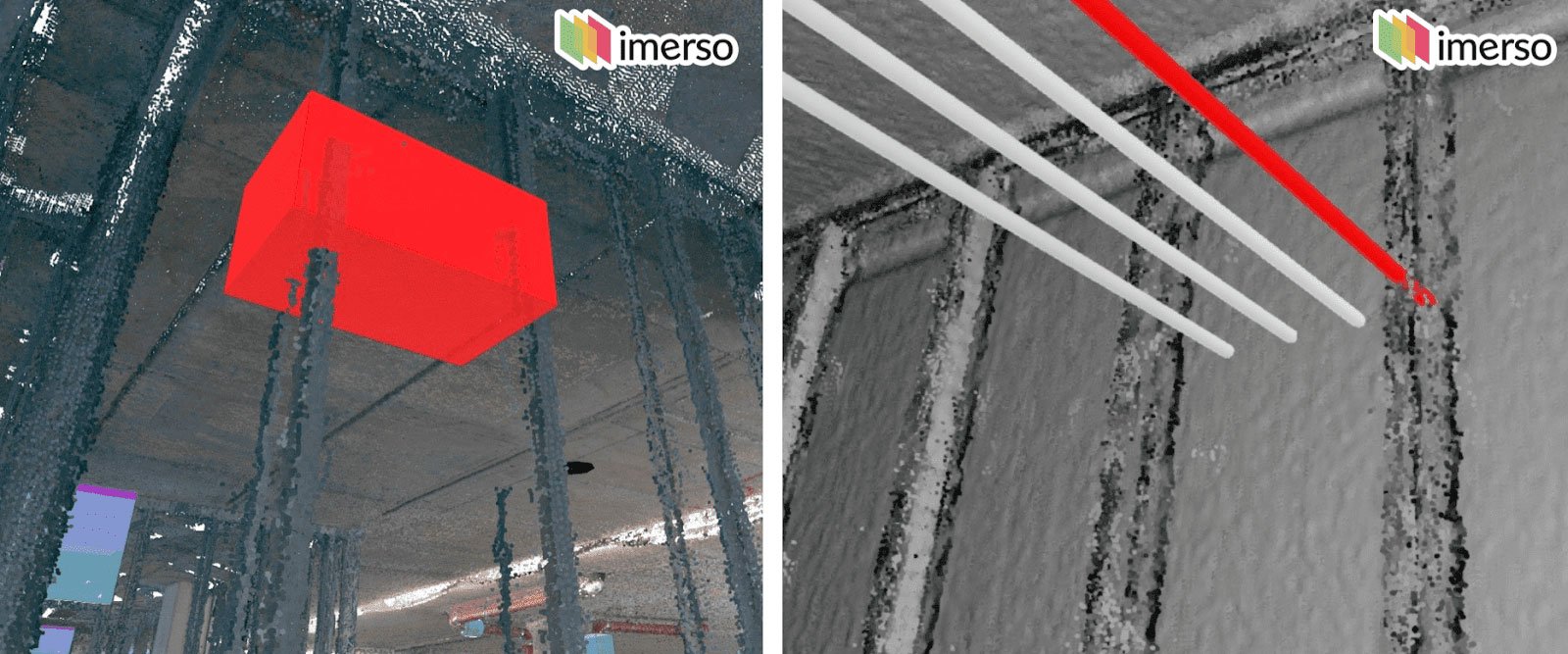

The news hit him like an icy blast. Their sister project, similar in scope but only half the size, was deeply in trouble. Mere weeks before handing the keys to the owner, inspectors had unearthed tens of thousands of incorrectly placed fire-stopping fixtures. It was a chilling revelation. Beyond the grim public image, the project now faced staggering costs and crippling delays to remedy an issue that should never have existed. The news had put his whole team on edge, and as project manager, his phone rang incessantly. The client requested assurances that their project was immune to such risks. But how could he confirm this? He was certain that the leaders of their sister project were equally blindsided, despite having rigorous protocols in place per the industry standard.

As he sipped his morning coffee, a thought arose. He had been experimenting with cutting-edge technology for monitoring work quality proactively. The system had excelled during the construction of the superstructure, and he had been expanding its applications at the site for months. Perhaps it was time to deploy it to ensure compliance of fire-stopping installations. With several thousand fire-rated walls paralleling those found deficient in the sister project, and their installation just beginning, he found a starting point.

Struggling to find available resources, he decided to first assign the task to a group of interns, instructing them to grab a 3D scanner and capture every room where fire-rated wall installations were in progress. The interns eyed the device, bewildered, asking, "Should we get a surveyor's help?" He pointed to the device's largest button and explained, "Extend the tripod, mount the device, and press this like taking a photo. It captures everything within a 50-meter radius. Do it two or three times for each room. Now, go!"

At lunch, the interns returned, brimming with excitement. They'd swiftly mastered the scanning process and boasted a tenfold increase in speed compared to their regular laborious manual checklists. They had captured every room. They assured him the data would be ready for review after lunch. With bated breath, he logged into the scanning platform, and it hit him. The screen blinked red. Dozens of metal frames were flagged, obstructing critical paths where technical equipment was planned to pass. Worse still, instead of merely cutting through the metal frames to make space, proper fire-blocking frames would need to be installed for the entire system to remain compliant. Without proper documentation, once the walls were closed up, he knew future teams could inadvertently slice through the metal frames, jeopardizing the fire rating and potentially dooming their project.

He couldn't afford that risk. He immediately shared the data with all relevant teams, demanding on-site corrections or design revisions. Scanning became a daily ritual. He knew the approach couldn't ensure that all risks would be eliminated, but every revelation was one less hidden menace haunting their site. In each case, a potential landmine was removed. Their modern approach had uncovered a better way to capture data, but now they needed to revolutionize the way their teams acted on it. The fight was far from over; it was time to convince all team leaders to embrace this new opportunity. Only time would tell if they could.

The Scare of the Creeping Slopes

The contractor leader stepped onto the construction site with a sense of confidence. The project was at the finishing line with the final visits by the owner prior to the takeover. It was a straightforward job, just a manufacturing warehouse, a place where the client's manufacturing systems would soon come to life. Now all final documentation had been submitted and the end was in sight.

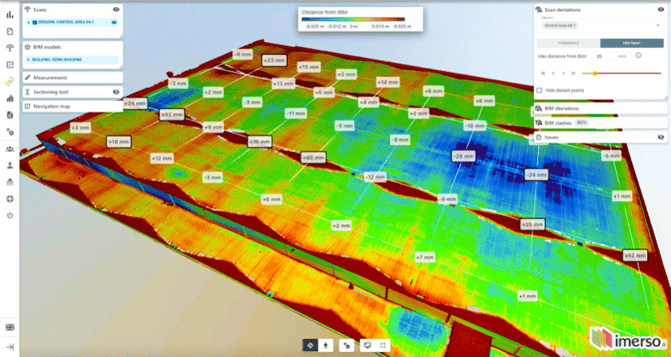

The owner's representative had a particular request in the past days – documentation regarding the surface levels. For a manufacturing facility, floor flatness was a matter of utmost importance. Any irregularity beyond tolerance could set off vibrations in the machinery, leading to faster wear and tear and soaring maintenance costs. There were other concerns, too, like ensuring that rainwater didn't pool on the roof, which had a distinctive wavy design. The contractor assured that everything was spot-on, but could only produce documentation from conventional manual spot-checks.

As the owner arrived, a mysterious device caught the contractor's eye – a small 3D laser scanner. The owner explained they'd use it to capture the entire floor and roof surfaces during the visit as part of their due diligence. A new software purchased by the owner would automatically calculate whether the physical building met the intended specifications. The contractor hadn't foreseen such technical finesse from his customer but could find no reasonable objection.

The results, when they finally appeared on the owner's laptop screen, left both men crestfallen. The finished building featured several instances that didn't match the submitted documentation, revealing numerous discrepancies. The floor surface displayed problematic elevations and depressions beyond the acceptable limits. The roof, with its undulating design, showed multiple areas where rainwater would pool, promising future damage.

The contractor knew the trouble these issues could brew after the handover – disputes, delays, and unforeseen costs. Most contracts provided a warranty period, but few owners could pinpoint quality issues with such precision. The deviations would have to be rectified promptly to avoid penalty delay fines and costly squabbles. He asked to be sent the data report and sprung into action.

From that day forward, the contractor traded traditional inspections for modern technology. No more last-minute surprises that could cost the company a fortune and tarnish its reputation. The contractor had learned a lesson in the most unexpected way, ensuring that precision and work quality would henceforth become the guiding principle in all his projects. If one photo is worth a thousand words, a laser scan is surely worth a thousand photos.

Do you have any spooky construction stories of your own?

Share them with us :)

About Imerso

Imerso is a software platform that combines BIM, Reality Capture, and AI technologies to automate construction site supervision and quality inspections with one simple workflow. We help construction companies cut project risks and delay costs with real-time monitoring of site status and work quality.

For additional reading, check out the 7 Powerful ways of using Imerso to supercharge your construction projects.

.png?width=350&height=147&name=Imerso_Logo_A4_White_Transp%201%20(1).png)