Imerso's place in the ecosystem

E.Klink and Imerso partnership

E.Klink had learned about the Norwegian technology company Imerso from Nikolaj Dehn, VDC Group Manager for Development at Per Aarsleff A/S, who had signed a license with the software provider earlier that year.

“The three main advantages of Imerso over other solutions are:

- There is no need for targets during the scanning process, making it much easier to do the laser scanning.

- The user interface is very intuitive, making it easy to include colleagues into projects.

- Controlling large areas and finding deviations is extremely effective.”

— Nikolaj Dehn, VDC Group Manager for Development at Per Aarsleff A/S

Leica BLK360.

First results

After the second month, the results were already impressive. E.Klink’s team, led by construction engineers Patrick Frydenlund and Chris Gordner, can now verify 100% of the ducts and air terminals within the same time that it took to verify just 15–20% in the past — a productivity increase of over 400%.

Imerso's place in the ecosystem

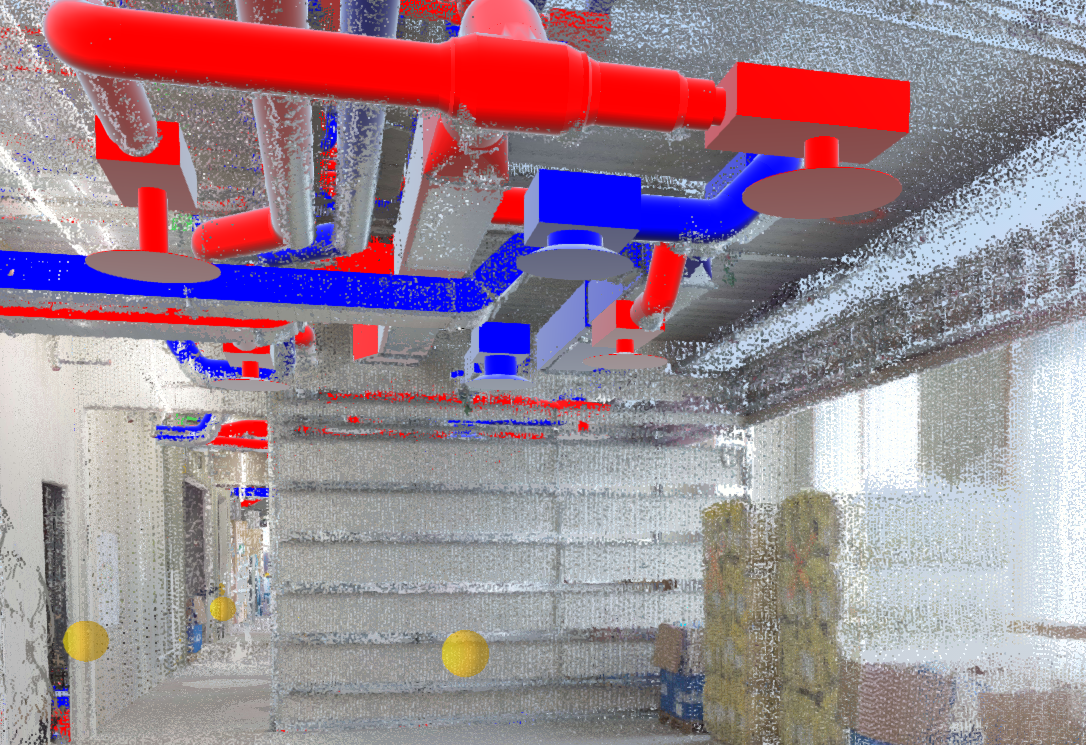

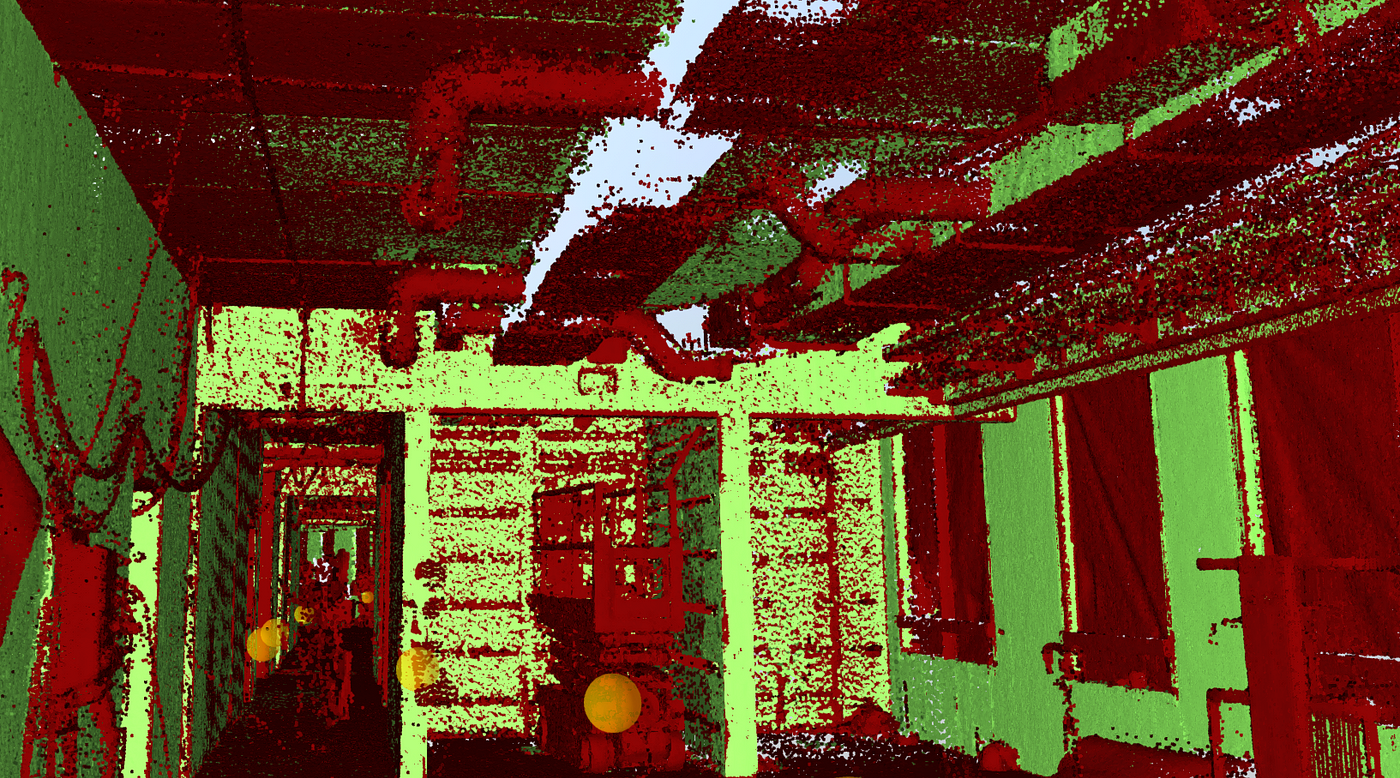

Looking at a more operational level, E.Klink’s workflow is divided into three parts: scanning, deviation detection and issue communication. A Leica BLK360, which can be operated with Imerso’s mobile app, is used by E.Klink employees to scan the construction sites. Afterwards, the laser scans are uploaded to Imerso’s platform where Chris Gordner and his colleagues analyse the results of Imerso’s Scan-vs-BIM deviation detection. Issues are then communicated via Dalux, which the company uses as their project management platform.

Besides the productivity gain throughout the production process, E.Klink now avoids unforeseen delays during the production phase. This new method also reduces the risk for warranty claims after the project is finished while having millimetre-precise documentation of the work.

.png?width=350&height=147&name=Imerso_Logo_A4_White_Transp%201%20(1).png)